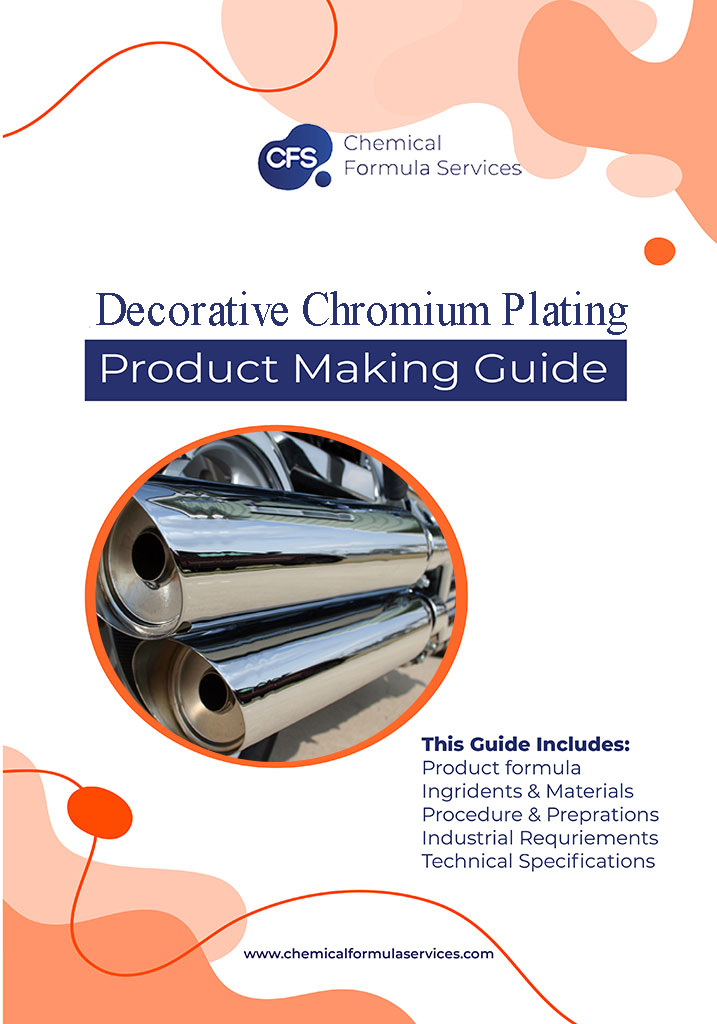

Decorative Chromium Plating Formulation

$ 65

Description

At CFS (Chemical Formula Services), we proudly present one of our most technically advanced and industry-proven systems — the Decorative Chrome Plating Formulation, representing decades of expertise in surface finishing chemistry and electrodeposition science.

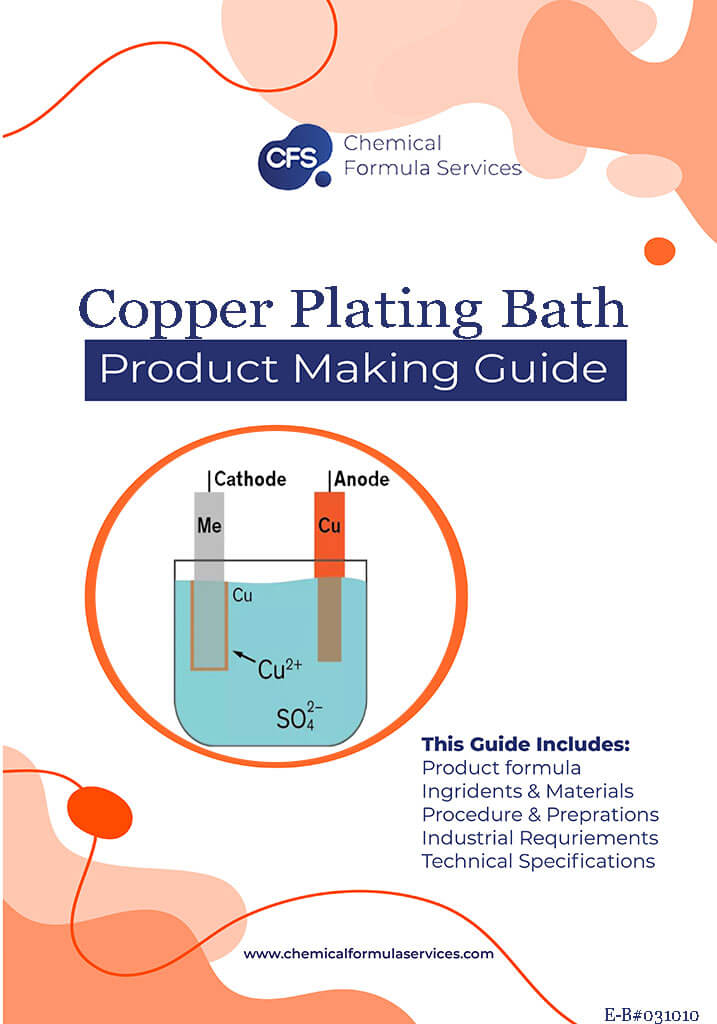

Decorative chrome plating stands as one of the most refined and enduring achievements in metal finishing technology. Unlike hard chromium coatings, which serve primarily functional purposes, decorative chromium is applied in ultra-thin layers (typically 0.13 to 1.25 μm) to achieve a brilliant, blue-white metallic appearance that delivers exceptional aesthetic appeal, tarnish resistance, and long-term corrosion protection.

Advanced Surface Engineering

CFS formulations are designed for use over optimized undercoating systems such as copper-nickel, semibright/bright nickel, or duplex nickel layers, which form the essential reflective and protective foundation beneath the chromium topcoat. These layers not only enhance the visual brilliance but also provide the primary barrier against corrosion, ensuring a mirror-like finish with outstanding durability.

Transition from Hexavalent to Trivalent Systems

Traditionally, decorative chromium plating has relied on hexavalent chromium technologies based on chromic anhydride (CrO₃). While these systems have long been valued for their reliability and deposit quality, CFS modern trivalent chromium formulations represent a new generation of eco-friendly chemistry.

Our Trivalent Chromium Plating Systems deliver:

-

Equivalent or superior brightness and color to traditional hexavalent deposits

-

Higher throwing and covering power

-

Safer, low-toxicity operation

-

Dramatically reduced environmental footprint

These innovations reflect the global movement toward sustainable surface finishing while maintaining the iconic blue-white brilliance associated with classic decorative chrome.

Precision-Controlled Process Parameters

CFS decorative chrome plating systems are engineered for precise control of:

-

Bath chemistry and metal ion concentration

-

Temperature and current density

-

Substrate activation and pretreatment

-

Additives for leveling, lustering, and deposit uniformity

Controlled microcracking and microporosity are deliberately incorporated into certain formulations to optimize corrosion behavior — enabling uniform nickel corrosion, preventing deep pitting, and extending the finish’s visible lifespan.

Comprehensive Technical Foundation

The CFS Decorative Chrome Plating Formula Package includes detailed guidance and fully tested formulations covering every technical aspect of the process:

-

Fundamentals of electrodeposition and surface preparation

-

Advanced formulations for both hexavalent and trivalent chromium baths

-

Additive systems and wetting agents for enhanced luster and leveling

-

Role and behavior of undercoating layers in multilayer systems

-

Techniques to control microcracking and microporosity

-

Process troubleshooting, defect diagnosis, and quality assurance protocols

-

Complete environmental, safety, and regulatory compliance guidelines for modern plating facilities

Applications

Suitable for a wide range of substrates, including:

-

Steel and stainless steel

-

Brass and copper alloys

-

Zinc die castings

-

Aluminum and plated plastics

These formulations and process parameters are ideal for producing decorative chrome finishes in automotive components, bathroom fittings, consumer appliances, hardware, and premium metal accessories.

Why Choose CFS

As a leading global provider of advanced chemical formulations, CFS offers:

-

Ready-to-scale, high-efficiency plating formulations

-

Technical data sheets (TDS) and process specification sheets (PSS)

-

Expert support in process optimization, bath control, and environmental compliance

-

Custom-tailored systems for both new plating facilities and upgrades of existing lines

Result

The CFS Decorative Chrome Plating System delivers:

-

Brilliant mirror finish

-

Enhanced corrosion protection

-

Exceptional adhesion and coverage

-

Eco-compliant chemistry

-

Long-term stability and repeatable performance

Whether your goal is to replicate the timeless blue-white luster of traditional chrome or adopt the next-generation trivalent technology, CFS formulations empower professional electroplaters, chemical formulators, and surface finishing engineers to achieve world-class results with confidence, consistency, and sustainability.