Austenitizing Salt Bath Formulation

$ 70

Price : 70.0 $

Description

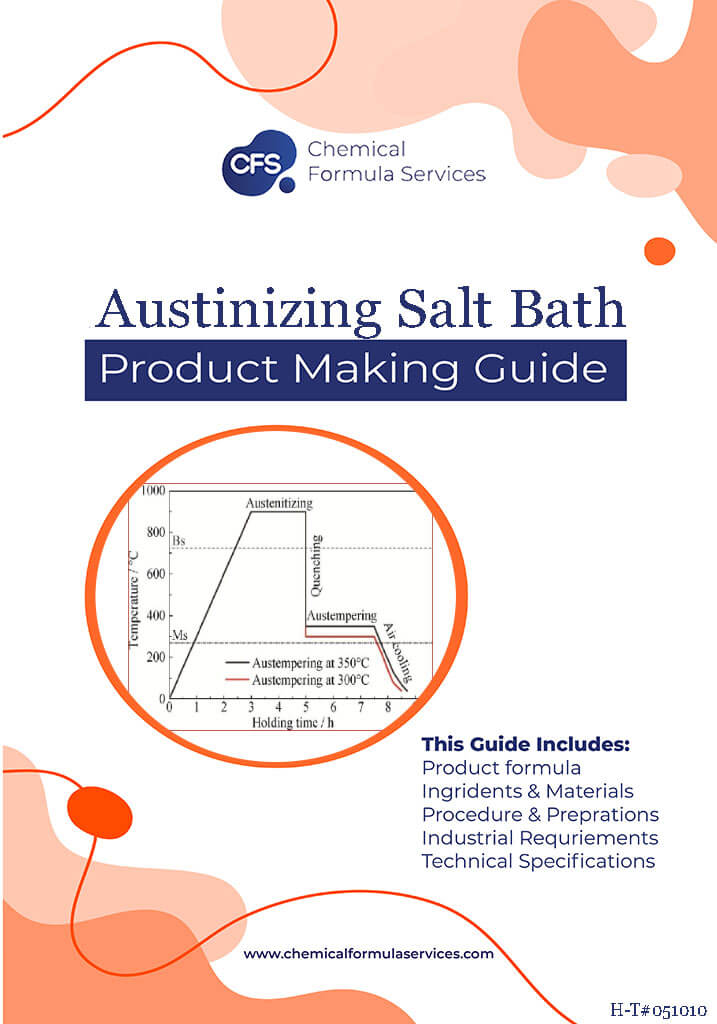

Austenitizing salt bath formulation is the process of heating steel to a temperature above its critical transformation temperature. This temperature varies depending on the specific steel composition. By heating the steel to this temperature range, the microstructure of the steel transforms from its initial state (which could be ferrite, pearlite, or other phases) into austenite, a solid solution of iron and carbon.

Austenitizing is typically performed to prepare the steel for subsequent heat treatment steps such as quenching and tempering. The goal is to dissolve any carbides or other precipitates present in the steel and obtain a fully austenitic structure. This transformation allows the subsequent heat treatment steps to have the desired effect on the steel’s properties.

A salt bath for tempering structural parts made of iron and steel treated in a cyanide-free or low-cyanide nitriding salt bath or other cyanide-containing salt bath.

This process is also useful if the construction part has previously been treated in cyanide containing salt baths, such as in carburization. The cyanide-containing salt that adheres to the surface of the build-up and is drawn into the heat bath is thus destroyed by oxidation so that the wash water used later is cyanide-free. The cyanide content in salt baths used for austenitization or carburization is limited to about 10% by weight (calculated as NaCN) because at high cyanide contents the salt containing cyanide and nitrate containing salt heating bath- An unusually violent reaction can occur between nitrates.

Austenitizing Salt Bath Formulation

The exact austenitizing temperature and soaking time will depend on the specific steel grade and the desired outcome. It is crucial to follow the recommended austenitizing parameters provided by the steel manufacturer or established industry guidelines for the specific steel alloy being processed.

During the austenitizing process, the steel is typically held at the austenitizing temperature for a specified time to ensure a uniform transformation. After the soaking time, the steel is then rapidly cooled (quenched) in a suitable medium such as oil, water, or air to freeze the austenitic structure in place.

Following the quenching step, the steel may undergo additional heat treatment processes such as tempering, which involves reheating the steel to a lower temperature to achieve the desired combination of hardness, strength, and toughness.

Heat Treatment salt bath composition

The heat treatment process, including austenitizing salt bath heat treatment pdf can have a significant impact on the mechanical properties and performance of the steel. Therefore, it is recommended to consult with a qualified metallurgist or heat treatment professional to ensure the correct procedures and parameters are followed for a specific steel alloy and intended application.